Advanced Air & Vacuum’s Prevost Air Piping Service

As the exclusive authorized dealer of Prevost Aluminum Air Piping products, Advanced Air & Vacuum is the leading provider of compressed air piping solutions in California, Arizona, and Las Vegas.

We specialize in designing and installing compressed air systems for a wide range of industrial applications, including automotive equipment, car washes, sandblasting, CNC machining, pneumatic conveying, food and beverage production, woodworking, and tire shops. Our experienced team develops customized Prevost piping plans tailored to meet your unique needs, ensuring efficient and reliable operation.

What is Prevost Air Piping?

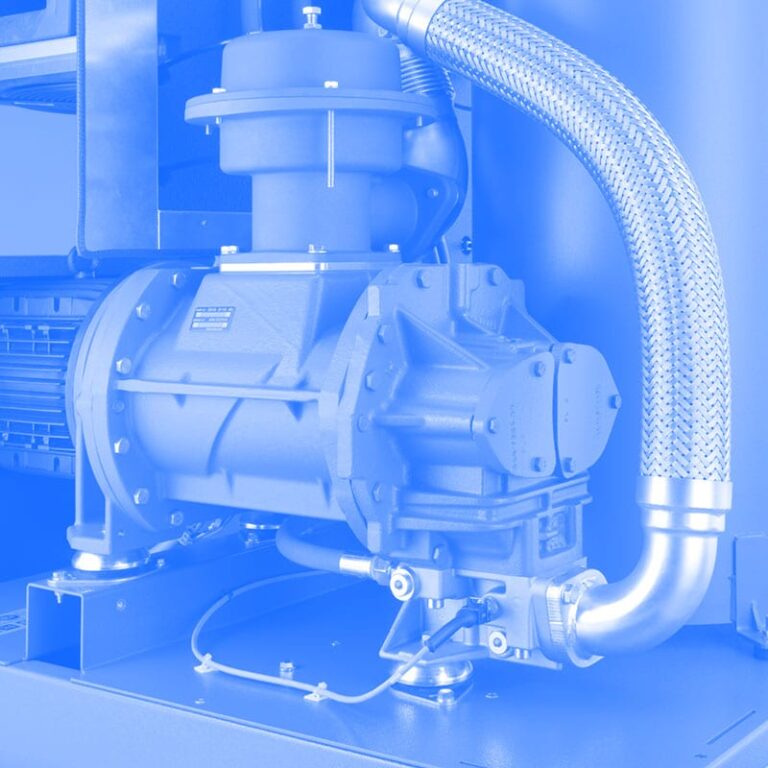

Prevost Air Piping is an innovative compressed air system built with high-quality, impact-resistant aluminum pipes designed for durability and a leak-free network. Its advanced engineering ensures optimal airflow, minimal pressure drops, and compatibility with a wide range of air tools and compressor lubricants, making it an ideal solution for even the most demanding environments.

CONNECTORS

AIR DISTRIBUTION

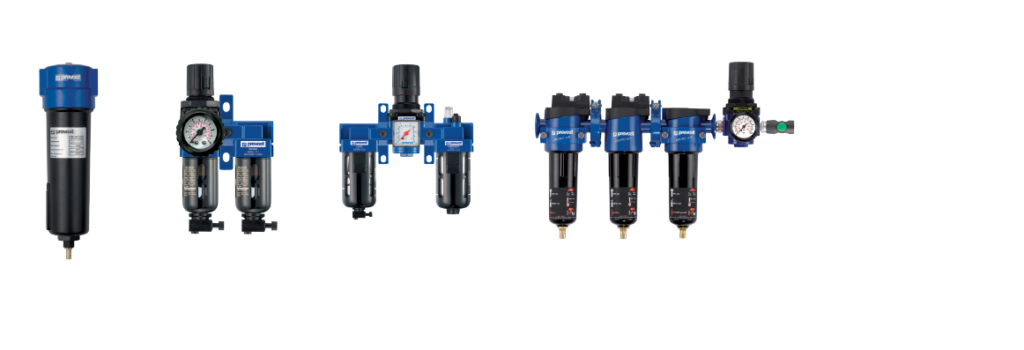

FILTRATION

Benefits of Prevost Air Piping Systems

Modular System

Prevost Air Piping features a modular system and a PPS Grip concept, providing secure, leak-free connections while allowing for quick installation and easy system modifications without specialized tools.

Reduced Energy Consumption

The smooth internal surface of the aluminum pipes reduces friction, optimizing airflow and cutting energy consumption. This makes it an ideal choice for industries requiring high performance and cost savings.

Efficiency & Maintenance

Prevost aluminum pipes are lightweight yet durable, reducing the risk of corrosion and extending system efficiency while minimizing long-term maintenance costs.

Our Prevost Services

Sales

As the exclusive authorized dealer in California, Arizona, and Las Vegas, we sell high-quality Prevost Air Piping Systems tailored to your specific needs.

Installation

We specialize in the installation of Prevost Air Piping Systems, ensuring that your compressed air network is set up efficiently, and according to your specifications.

Maintenance & Repair

We offer expert maintenance services to keep your Prevost system leak-free and energy-efficient, with emergency repairs available to minimize downtime.

Our Prevost Process

- Initial Assessment: Fill out our online form or call today for a direct consultation with our experts.

- Inspection: Our certified technicians conduct a thorough inspection of your compressed air system to identify the solutions that best fit your needs.

- Service: Based on the inspection, we provide the necessary service. From installing Prevost air piping networks tailored to your specifications to maintaining and repairing key components, we handle everything to ensure your system operates efficiently and reliably.

- Leave a Review: Your feedback is important to us. After your service, please leave a review to help us improve and continue delivering top-notch customer care.

Why Choose Advanced Air & Vacuum?

Comprehensive Service

Performing everything from installations and replacements to repairs and maintenance, we handle all aspects of the process, ensuring your Prevost piping is functioning at peak performance.

Reliability and Trust

We understand trust is the foundation of any good partnership, which is why we do everything in our power to be a reliable partner you can count on, maintaining the highest standards of integrity and transparency in all our servicing.

Customer Satisfaction

Your satisfaction is our top priority and we are committed to delivering exceptional services that exceed your expectations.

Contact Advanced Air & Vacuum Today!

If you are in California, Arizona, or Las Vegas and looking for a reliable provider of high-quality compressed air piping solutions, look no further than Advanced Air & Vacuum. With our expertise, experience, and commitment to quality, we can help you design and install a high-performance air system that meets your needs and exceeds your expectations.

Request a quote or call us today to learn more about our Prevost Air Piping solutions.