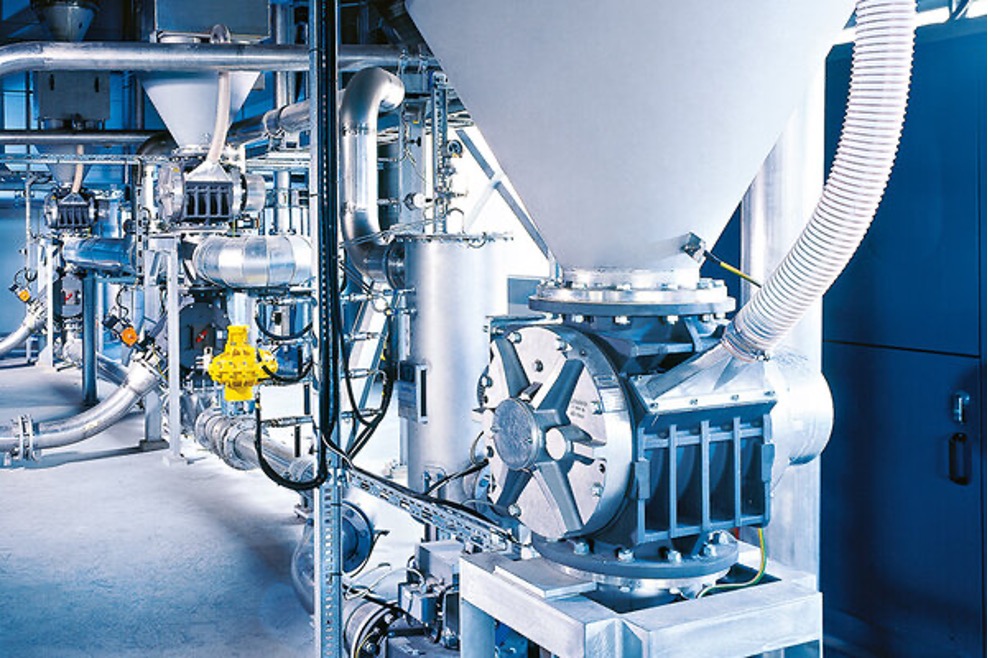

Air Compressors and Vacuum Pumps for Pneumatic Conveying

Advanced Air and Vacuum is a leading provider of industrial air compressors and vacuum pumps for Pneumatic Conveying Systems.

With a wide range of advanced technologies, we offer reliable and efficient solutions tailored to meet the specific needs of your industry. Our compressors ensure consistent air supply, while our vacuum pumps enable efficient material transfer. Whether it’s bulk material handling or process automation, our products deliver optimal performance and enhanced productivity. Trust Advanced Air and Vacuum for top-quality equipment that powers your pneumatic conveying systems with precision and reliability.

What is Pneumatic Conveying?

Pneumatic conveying is a method used to move bulk materials, like powders, granules, and other dry bulk solids, using pressure differences and a flow of air or other gases. It’s a bit like a giant version of sending bank notes or messages through those tube systems you sometimes see in older buildings or drive-through banks. Pneumatic conveying systems usually consist of four main components: a feeder or inlet, a conveyance line, an air mover, and a separator or receiver. The material to be moved is introduced into the system at the feeder, and then the air mover – which could be a fan, blower, or an air compressor – generates a flow of air or gas that carries the material through the conveyance line. At the end of the line, the material is separated from the air or gas flow and collected.

What Industries use Pneumatic Conveying?

Pneumatic conveying systems are used in a wide range of industries due to their ability to handle various types of materials and their flexibility in terms of routing. Some of the industries include:

- Food and Beverage: Conveying ingredients, like sugar, flour, or spices, and products like cereal or coffee.

- Pharmaceuticals: Handling active pharmaceutical ingredients, tablets, or capsules.

- Chemicals: Transporting various forms of chemicals safely and efficiently.

- Plastics: Moving plastic granules or pellets from storage to the molding machines.

- Power Generation: Transporting coal or biomass fuels in power plants.

- Metals & Minerals: Handling sand, cement, or other raw materials in the mining or metal processing industries.

Benefits of Pneumatic Conveying Systems

Pneumatic conveying systems offer several benefits that contribute to their widespread use across various industries. One key advantage being their efficiency, since these systems enable the quick transportation of materials while allowing for easy automation, which not only enhances productivity but also streamlines production processes.

Another significant benefit is the emphasis on safety and hygiene. Since pneumatic conveying systems are fully enclosed, they effectively minimize material exposure to external environments that could potentially increase contamination risks. Being fully enclosed, there is also far less of a risk for dust explosions in industries that handle combustible materials, ensuring a safer working environment.

Pneumatic conveying systems are also highly versatile in terms of the materials they can handle and the industries they can be utilized within. Whether it is fine powders or larger granules, these systems can be designed to transport a wide range of materials effectively, even hot or abrasive materials.

How are Air Compressors and Vacuum Pumps Used in Pneumatic Conveying?

Industrial air compressors and pneumatic vacuum pumps are two types of devices used in various industries for a variety of applications, but they operate based on different principles. However, they can be related because one can often be a source of power for the other. Below, we dive into the individual roles of air compressors and vacuum pumps in pneumatic conveying.

Industrial Air Compressors USE IN Pneumatic Conveying

An industrial air compressor converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized, or compressed, air. Air compressors function on the principle of forcing air into a container and reducing its volume, which leads to an increase in pressure. Once the maximum pressure is achieved, a port or valve opens, and the compressed air is discharged following the gradient from high to low pressure. This compressed air can then be used in a variety of ways across numerous industries, including manufacturing, automotive, construction, and many more.

INDUSTRIAL VACUUM PUMPS USE IN PNEUMATIC CONVEYING

A pneumatic vacuum pump, on the other hand, operates quite differently. Also known as a venturi vacuum pump, it creates a vacuum (an area of low pressure) by flowing compressed air through a special constricted section of the pump. As the compressed air moves through this narrow section, it speeds up, which reduces its pressure. This low-pressure area essentially becomes a vacuum.

The pneumatic vacuum pump relies on this vacuum for its operation. These pumps are used in a variety of applications like material handling (lifting, holding, moving objects), vacuum forming (in packaging or product molding), and industrial automation processes, among others. Check out the vacuum pumps that AAV carries here!

So, how do air compressors and vacuum pumps work together in pneumatic conveying? Well, a pneumatic vacuum pump often relies on an industrial air compressor to provide the compressed air it needs to create a vacuum. In this sense, the industrial air compressor can be seen as the power source for the pneumatic vacuum pump. It’s an excellent example of how different industrial tools can work together to perform a variety of tasks.

Choosing an Air Compressor for Pneumatic Conveying

Choosing the best type of industrial air compressor for pneumatic conveying can depend on a variety of factors, including the nature of the material to be conveyed, the distance and routing of the conveyance line, the rate at which the material needs to be moved, and other specific requirements of the system.

That said, the most commonly used types of air compressors in pneumatic conveying systems are positive displacement compressors, specifically rotary lobe blowers and rotary screw compressors. Read below for some additional information that will help you choose between the two!

Rotary Lobe Blowers

Also known as Roots blowers, these are widely used in pneumatic conveying systems, particularly in pressure systems. They operate by trapping a certain volume of air and then discharging it against the system pressure. They are generally quite efficient, reliable, and capable of achieving the relatively low pressures (typically under 15 psi) needed in most pneumatic conveying applications.

Rotary Screw Compressors

These are another common choice, particularly for larger systems and those requiring higher pressures. They work by trapping air between two interlocking screws, compressing it as it’s pushed along the screw’s length. They are more complex and typically more expensive than rotary lobe blowers, but they are capable of continuous operation and can efficiently achieve higher pressures and flow rates.

Contact AAV today for all Air Compressor and Vacuum Pump needs!

When choosing the air compressor for you, ultimately “best” choice will depend on the specific needs and constraints of your pneumatic conveying system. Need some help deciding between one of our air compressors? Contact Advanced Air & Vacuum today, and one of our service representatives will be more than happy to talk with you!