Table of Contents

The Short Answer: If you’ve ever pumped air into your car tires or utilized power tools, you’ve seen compressed air in action. In simplest terms, compressed air is regular, ambient air confined to a smaller volume, increasing its pressure. This energy-rich air is then stored and used as a power source in a variety of industrial and commercial applications.

Understanding compressed air is crucial because it isn’t just air – it’s a stored, potential energy source with the ability to do work and a lot of it. Whether it’s firing up pneumatic tools on a construction site or propelling high-speed production lines in manufacturing plants, compressed air plays an integral role in many processes. But what exactly is compressed air and how does it work? Let’s dive in to learn about this powerful energy source.

An In-Depth Look at Compressed Air

Compressing the Ambient Air

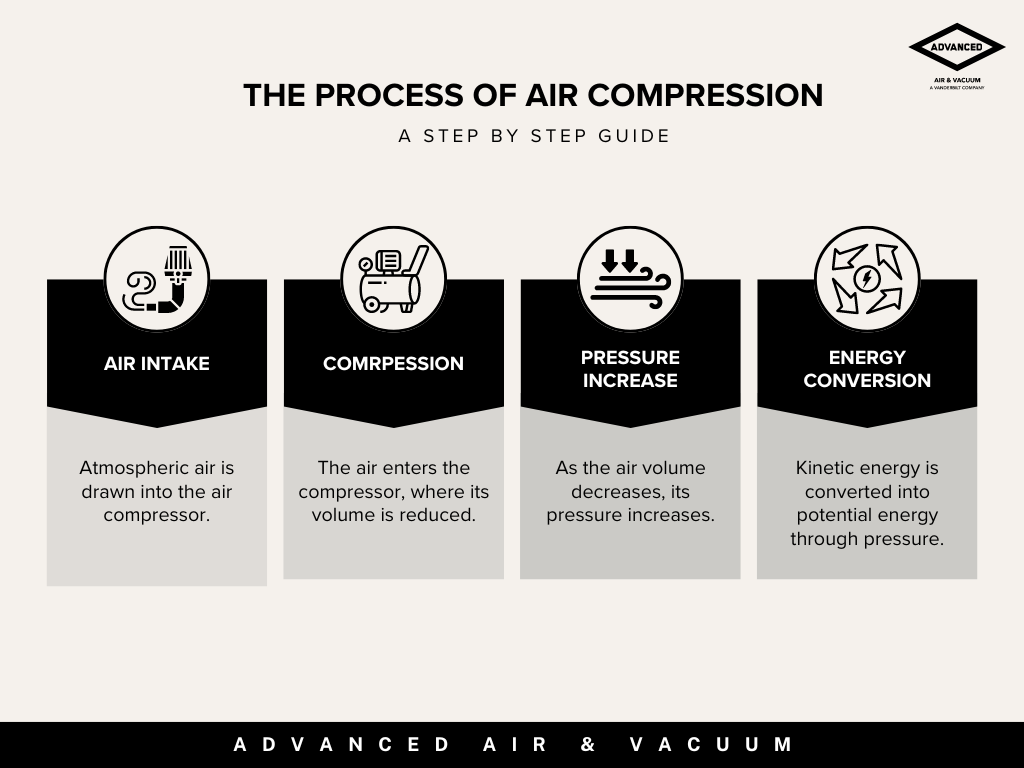

So, how exactly do we take ambient air and turn it into a source of power? The answer lies in the core mechanics of an air compressor, specifically a rotary screw compressor. This sophisticated machine traps ambient air between two obliquely aligned rotors, compressing it into a smaller volume which naturally increases its pressure.

The Role of Heat and Water Vapor

The process itself is more nuanced than it sounds. The ambient air absorbed by the compressor is a combination of gases, water vapor, and minute particulates. As it’s squeezed into a smaller space, the air molecules accelerate, leading to this everyday substance heating up. But this heat doesn’t linger – it gets absorbed by the compressor’s rotors and body, leaving the compressed air significantly cooler and drier than when it started. This transformation strips the air down to its core components, removing unwanted water vapor and impurities.

Storing the Compressed Air

But how is the compressed air stored? That’s where the air receiver tank comes in. This tank isn’t just a storage container. It acts as a stabilizer, buffering the system and controlling the air dispersal to ensure the delivery is smooth and consistent. Through airtight containment and precision control, the storage tank allows the potential energy within the compressed air to be harnessed, ready to be converted into kinetic energy when required.

To sum it all up, rotary screw compressors play a crucial role in creating compressed air. By condensing the volume and raising the pressure, these compressors convert regular ambient air into a versatile and potent energy source.

How Compressed Air Systems Work

Now that we’ve seen how compressed air is produced, let’s take a more detailed look at a typical compressed air system. An air compressor, the heart of the system, is where the transformation from ambient air to compressed air happens. But the compressor itself is just one part of a larger, interconnected system.

Components of the Compressed Air System

In addition to the air compressor, the system includes an air dryer, filter, and air storage or air receiver tank. The air dryer plays a crucial role in removing water vapor from the compressed air. Excessive moisture within the system can significantly impact its efficiency and the lifespan of the equipment.

The filter serves to remove any remaining impurities from the compressed air (think dust, oil, and other particles). These could potentially damage the machine or disrupt its operation. Maintaining a clean air source contributes to better efficiency and longer equipment life.

Next is the air storage or air receiver tank. As we’ve learned, this isn’t just a repository for compressed air. It serves as a buffer, maintaining a steady flow of air at a consistent pressure.

The Role of the Supply Side

Understanding the supply side of a compressed air system is crucial. It’s here that the ambient air is converted into a powerfully concentrated energy source. The supply side directly impacts the entire system’s efficiency. In a nutshell, the supply side comprises the air intake, air compressor, aftercooler, air dryer, and air receiver tank. Well-maintained equipment on the supply side increases system efficiency, reducing energy costs and ensuring a reliable source of energy for various applications.

So, to summarize, a compressed air system is a complex yet efficient setup where ambient air is transformed into a powerful, versatile energy source. The harmony between its various components ensures consistent, reliable performance, making compressed air systems indispensable in many industries.

Different Uses of Compressed Air

Compressed air enjoys a wide array of applications, but it’s often most visibly associated with the familiar hiss and buzz of pneumatic tools and machinery. However, its utility extends far beyond the toolbox. Giving life to applications that range from everyday commercial uses to large-scale industrial processes, compressed air proves its versatility.

Diverse Applications in Business and Industry

Consider the behind-the-scenes operations at manufacturing plants, for example. The production line, powered by compressed air, allows for the swift and efficient assembly of products. Companies are even using compressed air as a clean, sustainable energy source, harnessing its power to drive manufacturing processes and significantly cut back on industrial electricity consumption.

In the automotive industry, compressed air is essential for numerous operations, particularly in auto shops and tire shops. Automotive garages depend on air compressors to power hydraulic car lifts, making vehicle repairs and maintenance more efficient and safe. In tire shops, air compressors are used to inflate tires quickly and accurately, ensuring optimal pressure for safe driving. This versatile tool not only improves workflow but also enhances productivity, making it indispensable for businesses in the automotive sector.

In the medical field, compressed air is relied upon for several critical functions, from ventilators in hospitals to respiratory devices for home healthcare. Medical air compressors, specifically designed to meet stringent hygienic standards, ensure that safe, clean, compressed air is always available in life-saving applications.

When it comes to recreational activities, compressed air plays a pivotal role as well. Dive shops, for example, utilize high-pressure air compressors to fill scuba tanks, providing divers with the necessary air supply during underwater exploration.

The End-User Consideration

Understanding the needs of the end user is crucial to harnessing the power of compressed air. The air system used for powering pneumatic tools on a construction site would vary greatly from that in a delicate medical setting or a bustling manufacturing plant. A key aspect of utilizing compressed air is ensuring that the system matches the application flawlessly, to deliver consistent, reliable performance.

Overall, the applications of compressed air are as varied as they are crucial. Spanning diverse sectors and processes, this superb energy source continues to drive efficiency and performance in multi-faceted applications.

How AAV Can Help Your Business Harness the Power of Compressed Air

At Advanced Air & Vacuum, we understand the role of a well-optimized compressed air system in achieving greater operational efficiency. Serving California, Arizona, and Las Vegas, our portfolio includes a diverse range of air compressors from top manufacturers like Atlas Copco and Quincy. We carefully select the equipment that fits your business’s specific needs, whether it’s for an industrial facility or a small business. Our goal isn’t just to be a supplier, but to be your trusted partner in enhancing business operations, productivity, and energy efficiency.

We prioritize a personalized approach to each project, looking beyond the surface to understand your niche requirements. Our dedicated team is always on hand, delivering fast, reliable support and services including air compressor repairs, maintenance, and installations.

Get in touch with AAV today – let’s work together to power your business with compressed air.