Table of Contents

Mobility and fast response times can make or break a good service truck. Having a reliable air compressor that can handle the specific needs of diverse tasks can make a massive difference in the overall performance and efficiency of the service vehicle. The key is to ensure that your air compressor setup aligns with the demands of the tasks your service truck typically handles.

The Short Answer: The best all-around air compressor setup places the compressor in a central, well-ventilated area with easy access for maintenance and minimal noise disruption. Run piping overhead or along walls in a loop design for consistent air pressure and efficient delivery to all workstations. However, the optimal setup will still depend on your business’s specific compressed air applications and usage frequency.

This guide aims to provide a comprehensive overview of how to choose the correct air compressor for your service truck and how to set it up correctly. Before we delve into choosing the right compressor and the setup process, it’s important to establish what an air compressor is and its importance in the context of a service truck.

Choosing the Right Service Truck Air Compressor

Choosing the right air compressor for your service truck is an endeavor that requires thorough attention. It involves several factors to contend with, including the specific needs of the truck, anticipated duties, truck engine’s capacity, power requirement for equipment, and frequency of compressor use.

Identifying the Types of Air Compressors Suitable for Service Trucks

- Rotary Screw Air Compressor: Excellent for continuous-duty applications where consistent airflow is essential. Its ability to deliver high volumes of air without a large storage tank makes it ideal for demanding jobs like pneumatic tools or spray painting.

- C Compressor: Compact, lightweight, and versatile, making it perfect for service trucks that require a balance between performance and minimizing added weight. It’s a good choice for mobile setups that need portability.

- Electric Compressor: A quieter option for areas with consistent power supply access, suitable for urban or industrial environments where noise restrictions and environmental considerations are factors. It’s great for lighter or intermittent usage scenarios.

Considering the Duty Cycle

The duty cycle brings to the fore the duration that your air compressor can run in a full cycle, including the cooling down or rest periods. The higher the duty cycle, the longer the compressor can continuously function without requiring a break.

Power Requirement Essentials

Knowing how much power your air compressor needs is critical. This is because your engine will need to power both the truck and the air compressor. Matching the power requirement with what the engine can provide is fundamental to prevent any risk of overloading the engine.

Identifying Your Specific Needs

Evaluate the tasks that your service truck normally attends to. If these tasks entail the use of air tools (like an impact wrench or a grease gun) that necessitate a specific PSI or CFM, your air compressor must align with these specific needs.

How to Setup a Service Truck Air Compressor

Implementing a successful service truck air compressor setup isn’t just about choosing the right compressor. Every secondary component ties in to establish an efficient and safe system. Here is a step-by-step guide.

Understanding the Necessary Components

In addition to your picked air compressor, these elements form the core of your setup:

Gallon tank: The tank holds the compressed air. Their capacity in gallons may vary, and the one you need depends on your specific usage requirements.

Hose reel: A hose reel helps you to easily deploy and retract your compressor’s air hose, making it a vital part of your setup.

Battery charger: To supply ample power to your compressor, a reliable battery charger is important.

Air tank: Your air tank acts as a reservoir to store and release compressed air as needed.

Setting Up Your Air Compressor Correctly

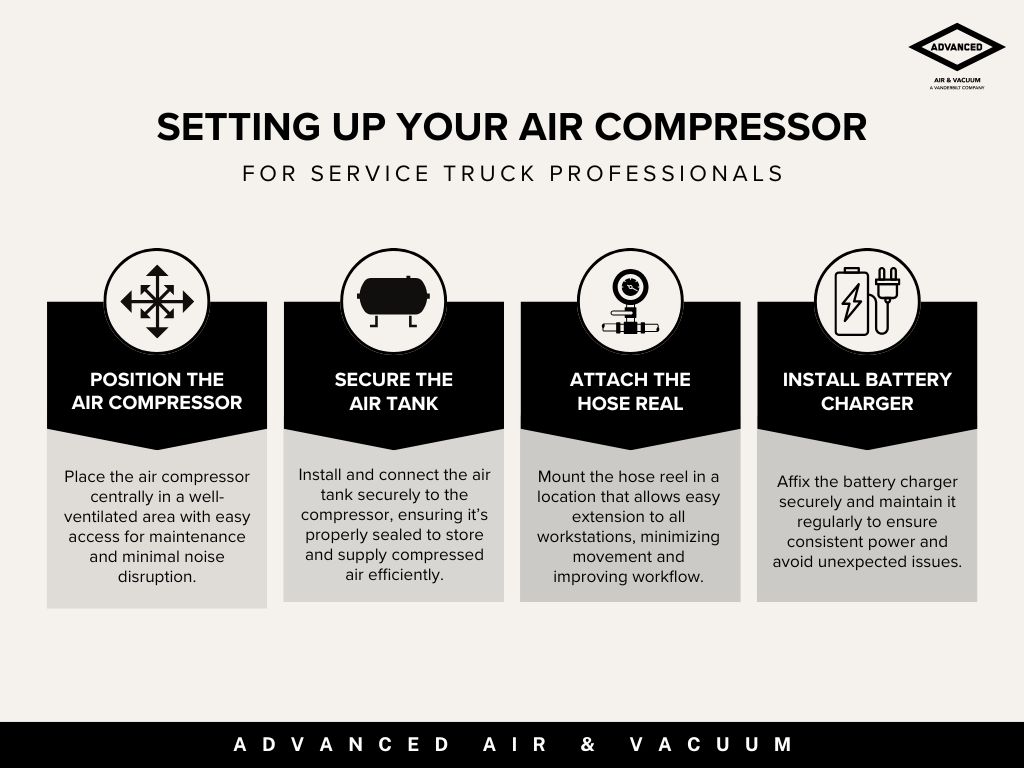

Step 1: Position the compressor centrally in a well-ventilated space, easily reachable for maintenance.

Step 2: Secure the gallon tank and make sure it’s connected correctly to the compressor.

Step 3: Connect the hose reel. It should be reachable enough to extend to all your workstations.

Step 4: Affix the battery charger properly. Make sure it’s regularly maintained to avoid power issues.

Step 5: Combine the air tank ensuring it’s well-fit, ready to store, and supply the much-needed compressed air.

Never Compromise on Safety

Safety is a top concern for every business. Always keep an eye on the pressure switch to prevent exceeding recommended limits. Your service body’s safety is equally vital; do not overload your truck bed, and check it regularly for damage. Ensure proper ventilation for operation and regularized maintenance for a safe, noise-minimal compressor setup.

Why Service Trucks Need a Built-in Air Compressor

An air compressor is not just an add-on for a service truck; it’s an integral part that amplifies its service potential. Here, we explore the various applications of a mobile service truck equipped with an air compressor.

What Service Trucks Need an Air Compressor?

Use of Air Tools: Pneumatic tools, such as impact wrenches or grease guns, run efficiently on compressed air. An on-board air compressor makes it possible to power these tools wherever your service truck might be.

Fuel Tank Inflation: Whether it’s a tractor tire, a regular truck tire, or any other type of tire, a service truck with a built-in air compressor can deal with tire inflation tasks with surprising ease. Having an onboard air compressor allows you to maintain optimal tire pressures at all times, drastically improving vehicle safety and performance.

Use of Hydraulic Pump and Hydraulic Crane: Service trucks are often equipped with hydraulic systems, such as hydraulic pumps and cranes. An air compressor provides the necessary power to run these hydraulic systems smoothly.

Servicing Multiple Locations: Whether it’s a flat bed situation or a medium-sized shop, your service truck is equipped to handle it. Combined with an air compressor, it can function as a mobile workstation, ready to undertake a variety of tasks at various locations.

While these applications merely scratch the surface of what’s possible with a service truck air compressor, they highlight why such a setup can boost the productivity and functionality of your service vehicle. After all, an air compressor is not a luxury for your service truck; it’s a necessity.

Choose Advanced Air & Vacuum for Your Service Truck Air Compressor Needs

At Advanced Air & Vacuum, we deliver more than air compressors, we deliver custom solutions tailored to elevate your business operations. As a trusted service truck partner, we can understand your business’s unique needs and connect you with the perfect air compressor.

Our team of experts doesn’t just deliver the unit and leave you to figure out the setup. Instead, we handle installation so that your new air compressor integrates smoothly into your existing operations, maximizing its efficiency and benefits from day one. Once your setup is perfectly calibrated and operating smoothly, our commitment doesn’t end there either. Advanced Air & Vacuum remains a trusted ally, ready at a moment’s notice for any maintenance, repair, or replacement needs that may arise.

Investing with Advanced Air & Vacuum is not merely about buying an air compressor; it’s about making a strategic decision towards elevating the productivity and efficiency of your service truck operations. Contact Advanced Air & Vacuum today and discover a partnership that will drive your business’ growth.

Article written 12/03/2024:

Article written 12/03/2024: With over 15 years of experience, Joseph is an expert in air compressor equipment, vacuum pumps, and pneumatic systems, possessing a unique blend of technical knowledge and practical skills. As a pneumatic system energy auditor and designer, he is proficient in diagnosing system inefficiencies, optimizing performance, and designing tailored solutions to meet clients' needs.

See more See less