Table of Contents

Is your motor humming or just making an odd noise but failing to start? It can be a telltale sign of faulty components or that it is time for rewinding or a full replacement.

An electric motor is a crucial component in many devices and CNC machinery. A humming motor is less efficient and can lead to more serious issues like overheating and even a complete breakdown. That’s why understanding why your motor is humming and knowing how to fix the problem is key to keeping your machinery in working order.

The Short Answer: Motor humming typically indicates an electrical or mechanical problem that results in the motor winding up but not kicking into full operation. Anything from a faulty centrifugal switch, a bad capacitor, an alignment issue with the motor shaft, or other mechanical failures could be responsible for the unusual hum.

A Closer Look at Motor Humming

Understanding Motor Operation

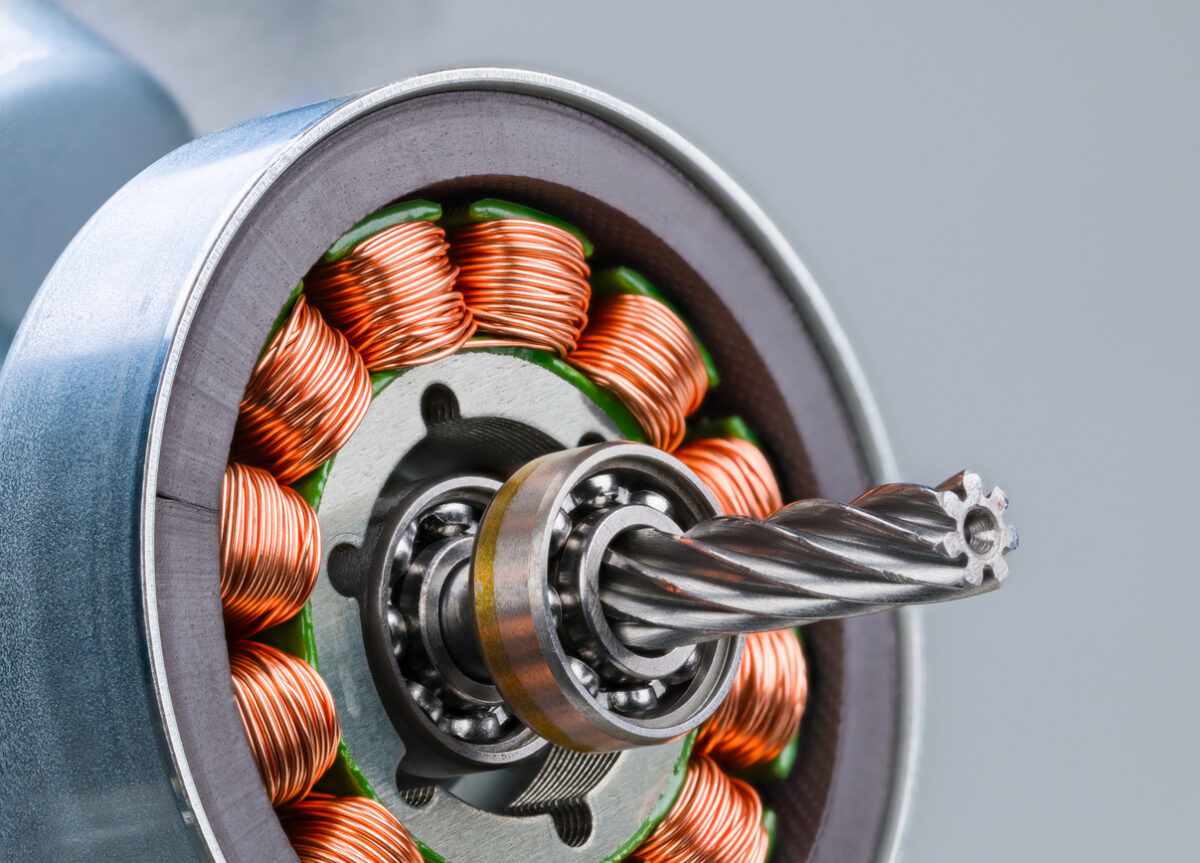

Motors are fundamental components in countless machines and devices, converting electrical energy into mechanical motion. They come in various types, such as AC motors, DC motors, and stepper motors, each designed for specific applications and performance characteristics. Key components of a motor include the stator, rotor, bearings, and windings, all working together to produce motion. Proper maintenance, including lubrication, alignment, and regular inspections, is crucial for ensuring motor efficiency and longevity. Recognizing signs of wear and addressing issues promptly can prevent costly repairs and downtime.

The Relevance of Motor Winding

The centrifugal switch and the start capacitor both play a key role in triggering the motor winding. This winding process is what allows your motor to maintain its operating speed. An issue with either of them can give rise to the humming problem.

Understanding the Origin of Noise

Armed with some background information, you’re now in a position to commence the detective work – tracing the source of the humming noise. Not all humming is created equal, so it’s crucial to understand whether it’s originating from the motor, shaft, capacitor, or elsewhere.

Identifying the Source of the Humming Noise & Fixing It

Start by Examing the Motor

Start your investigation with the motor. Consider these questions as you examine your motor:

Q: Is the humming sound being emitted from the motor when it’s operating at high speed or low speed?

A: If the humming occurs at high speed, it could indicate issues with the motor’s ability to handle higher loads or potential imbalance in the motor’s components at higher RPMs. If the humming occurs at low speed, it could suggest problems with maintaining stable operation at lower loads or issues with the motor’s drive or control circuitry that regulates lower speeds.

Q: Is the noise more noticeable during startup or when it’s been running for a while?

A: If the noise is more noticeable during startup, this could mean that the problem is coming from the motor’s initial power surge. If the noise occurs after running for a while, it could mean there are thermal issues or wear-related problems.

Q: If your motor’s a stepper motor, do fluctuations in speed or operating conditions affect the hum?

A: This could mean that the problem is coming from the motor’s driver or controller.

Identifying when and how the humming occurs helps narrow down potential causes, making it easier to target specific components and issues during further analysis. Now we will take a look at some of the most likely problem components and how to fix them.

Check the Centrifugal Switch

The centrifugal switch, a component in single-phase electric motors, disconnects the start winding from the circuit as soon as the motor reaches approximately 70-80% of its rated speed. If this switch happens to be worn out or impaired in any way, it can result in the humming noise we’re discussing.

Solution: Inspect the centrifugal switch for wear and tear. The centrifugal switch can be found inside the motor housing, typically mounted on the motor’s rotor or shaft. If damaged, replace the switch to ensure proper disconnection of the start winding.

Check the Start & Run Capacitor

Similar to the centrifugal switch, the start and run capacitors are integral to the smooth operation of your motor. The start capacitor provides the extra voltage required at startup to power on the motor, while the run capacitor helps maintain a consistent voltage supply during operation. A faulty capacitor – whether it’s the wrong size, blown, or damaged – can be the root cause of your motor hum.

Solution: Test and replace any faulty capacitors. Both the start and run capacitors are usually located on the exterior of the motor housing, often in dedicated metal or plastic casings.

Check the Motor Shaft

Next up, inspect the motor shaft. A humming motor shaft will often be a result of bearing problems. An open motor, for instance, whose bearings aren’t adequately lubricated could emit a humming noise. Another sign of a bearing problem could be an unusually worn-out/unaligned motor shaft or any visible damage for that matter, ringing the alarm bell for some much-needed maintenance or repair work.

Solution: Lubricate the motor shaft bearings regularly (the motor shaft can be found running through the center of the motor unit). Replace worn-out or damaged bearings and realign the motor shaft to prevent humming.

Spotting Other Potential Hum-Creators

Also, components such as the fan, fuel pump, or AC might be indirectly contributing to the hum. If a noisy fuel pump is struggling due to a clogged line filter, it could resonate through the motor casing, creating a secondary humming noise.

Solution: Inspect and clean the line filters in the fuel pump. Check other related components like the fan and air conditioner for issues that might be causing secondary vibrations or noises.

When to Consider Motor Rewinding or Replacement

No matter how impeccably we troubleshoot and tend to our motors, sometimes, the situation demands a more hard-hitting action, such as considering a motor rewind or even a replacement. Analyzing the main cause of the hum, the condition of your motor, and considering the cost-effectiveness is vital before making a decision.

Motor Rewinding

A motor rewind involves replacing the motor windings to restore the motor to its optimum performance. Certain kinds of humming problems might necessitate a motor rewind. For instance, if the buzzing noise is a result of worn-out motor windings, a motor rewind might be a viable solution. Advanced Air & Vacuum, with its exceptional motor rewinding services, provides solutions for a variety of motors.

Motor Replacement

On the other hand, if your motor is outdated, has completed its estimated life span, or the cost of repair seems prohibitive, a replacement might make more sense. A persistent hum, despite troubleshooting or repairs, could signal the need for a new motor.

Contact Advanced Air & Vacuum Today!

Whether it’s a replacement motor you need, or you want to revive your old motor with a motor rewind, Advanced Air & Vacuum can provide a tailored solution, ensuring your equipment performs at peak efficiency.