Figuring out how to use a vacuum pump can be a daunting task; however, with the correct guidance, it’s simpler than it seems. Vacuum pumps play an integral role in numerous applications such as in laboratories for vacuum filtration and in many industrial processes. In this post, we break down the essentials of understanding and using vacuum pumps effectively.

These handy tools have various uses such as in a vacuum distillation process for food and beverage production. While it might sound like a complex piece of machinery, with the right instructions and safety measures, using a vacuum pump is quite straightforward.

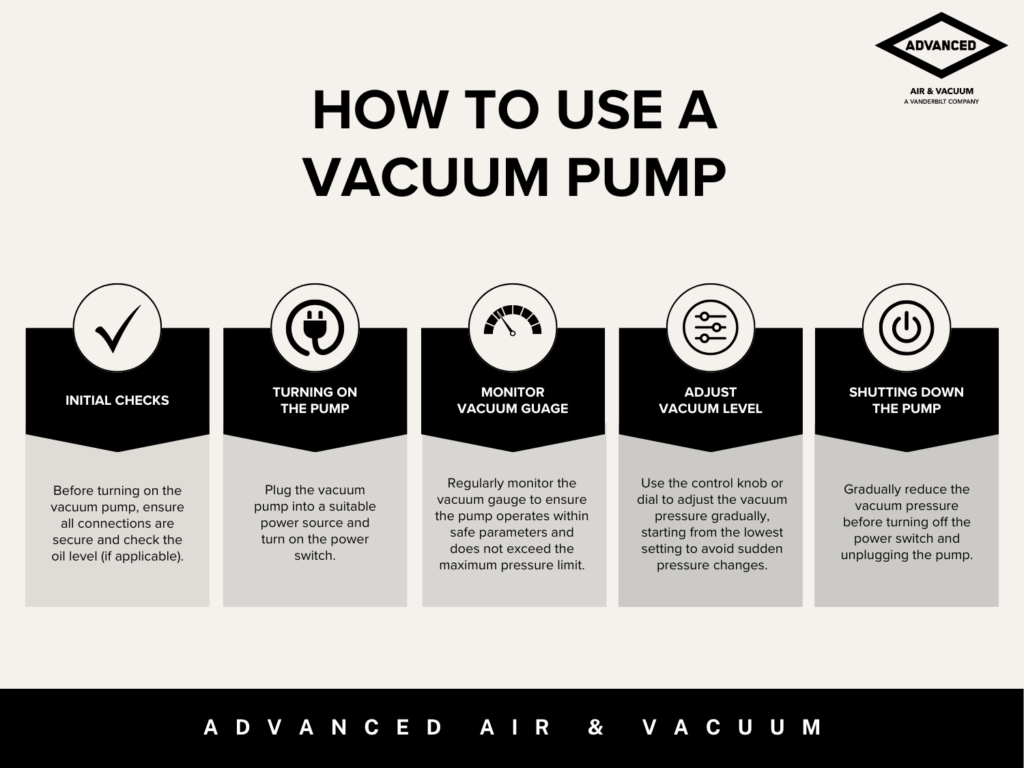

The Short Answer: So, how does one use a vacuum pump? There are some crucial steps to follow:

- Setup and check connections/oil level

- Turn on the pump by hitting the power switch

- Turn up the vacuum level gradually to avoid sudden pressure charges

- To shut down, gradually reduce the vacuum level

Understanding Vacuum Pumps & Their Role

Vacuum Pumps: Core Functionality and Operations

At the heart of it, a vac pump is engineered to create a controlled vacuum environment, enabling precision, efficiency, and reliability in numerous critical applications. Although the essential function remains the same, the operating mechanisms differ vastly across various types of vacuum pumps.

The operating principle involves creating a low-pressure area (a vacuum) into which a gas or fluid naturally moves to occupy from a high-pressure region. Vacuum pumps transport these molecules from the vacuum side to the exhaust side, consequently creating an ever-increasing vacuum as more and more molecules are removed.

The two main types include positive displacement pumps and momentum transfer pumps. Positive displacement pumps, like rotary vane pumps and piston pumps, work by repeatedly expanding a cavity, allowing gases to flow out of the chamber, then sealing the cavity, and exhausting it to the atmosphere. In contrast, momentum transfer pumps, such as turbo pumps, operate by increasing the speed of the gas molecules thereby creating a pressure gradient that pushes them from the vacuum side to the exhaust side.

The Various Applications of Vacuum Pumps

Beyond their simple definition and operational methods, vacuum pumps play an instrumental role in numerous industrial, scientific, and everyday applications.

Scientific & Medical Use

In science, high vacuum environments are essential for experiments in particle physics, quantum physics, and atomic energy modeling. These environments are also crucial in electron microscopy which allows scientists to see structures at the molecular level. Additionally, hospitals use vacuum pumps to create suction for surgical procedures and provide clean, uninterrupted power supply.

Manufacturing & Industrial Use

In many industrial and maintenance settings, vacuum pumps and air compressors are used together to enhance operational efficiency and achieve specific outcomes. They are crucial in vacuum furnaces for the heat treatment of metals, providing a high vacuum environment that reduces undesirable chemical reactions and yields cleaner finishes. Additionally, they play a significant role in processes like vacuum forming, packaging, and degassing, where removing air helps mold materials accurately, preserve products, and eliminate gas bubbles. In combined systems, vacuum pumps and air compressors work together in applications such as pneumatic conveying and HVAC systems, where vacuum pumps evacuate air and moisture while air compressors provide the necessary pressure, ensuring efficient and reliable operations.

The Importance of Vacuum Pumps in Today’s World

To sum it up, vacuum pumps are far more ubiquitous than most of us realize. They’re the unseen, yet vital component that drives a host of our modern technologies. Understanding the functioning and diverse applications of vacuum pumps opens up our awareness to these fundamental devices that silently, yet indispensably, shape many aspects of our lives. Once equipped with this knowledge, using a vacuum pump effectively will become significantly easier.

How to Use a Vacuum Pump

Setup and Installation

Before diving into the manipulation of a vacuum pump, proper setup and installation are key. Most vacuum pumps consist of two essential parts: the main body or the pump and the motor that drives it. Placing the pump on a stable, level surface near an electrical outlet is always a good start. It’s also important to ensure you have appropriate power supply matching to the pump’s specifications.

Connecting the vacuum hose and the check valve to the pump marks the next step. The check valve, a crucial component, prevents the backflow of the pumped substance when the pump is off. Here, make sure the connections are tight and secure.

Running a Vacuum Pump

Once the installation is complete, using a vacuum pump becomes quite straightforward. Here’s how to get started and ensure efficient operation:

- Initial Checks: Before turning on the vacuum pump, ensure all connections are secure and check the oil level (if applicable).

- Turning On the Pump: Plug the vacuum pump into a suitable power source and turn on the power switch.

- Monitoring the Vacuum Gauge: Regularly monitor the vacuum gauge to ensure the pump operates within safe parameters and does not exceed the maximum pressure limit.

- Adjusting the Vacuum Level: Use the control knob or dial to adjust the vacuum pressure gradually, starting from the lowest setting to avoid sudden pressure changes.

- Shutting Down the Pump: Gradually reduce the vacuum pressure before turning off the power switch and unplugging the pump.

By following these steps, you can ensure the efficient and safe operation of your vacuum pump, maintaining its longevity and performance.

Regular Maintenance and Safe Use

An integral part of using a vacuum pump involves its maintenance. Regular inspections are necessary to ensure proper function. Replacing pump oil periodically, and making sure filters are free from debris is essential. Be wary of any unusual noise or vibrations when the pump runs, as they often flag potential problems.

When performing maintenance inspections, look out for the following:

- Oil Level and Quality: Check and replace the pump oil regularly.

- Clean Filters: Ensure filters are free from debris.

- Connections and Seals: Inspect for wear or leaks.

- Unusual Noises or Vibrations: Identify and address potential problems.

- Vacuum Gauge Accuracy: Verify the gauge readings and maintain safe operating parameters.

How Advanced Air & Vacuum Can Help

Now that you understand the basics of vacuum pumps and how to use them, you might wonder where you can turn to for acquiring these vital devices or servicing an existing one. That’s where Advanced Air & Vacuum steps in.

Advanced Air & Vacuum is your one-stop solution for all your vacuum pump needs. We offer installation services to ensure your pump is set up safely and efficiently. Once it’s up and running, our certified technicians can take care of routine maintenance to ensure its longevity and efficiency. If you encounter any issues, our repair services will provide a quick and professional remedy.

By teaming up with Advanced Air & Vacuum, you are investing in top-quality products and services that will give you peace of mind in knowing that you have industry experts supporting your business. Contact us today and discover the difference we can make to your vacuum pump’s efficiency!