If you do a lot of auto detailing, you know that an air compressor can be very handy, from interior detailing such as cleaning floor mats and fabric upholstery to adding pressure to steam cleaning processes in the vehicle engine compartment. The professional detailer knows that the difference between the care and attention they give to every square inch of the vehicle is vital to their business, because otherwise the owner may as well just go to the car wash for their cleaning needs.

The enormous power that is available in an air compressor moves many cubic feet of air into a high-pressure system, making it much easier to blow debris out of tight spaces in a car interior. One might say that an air compressor is just as essential to the professional detailer as a microfiber towel, vacuum cleaner, or similar detailing tools. It even works well for mobile auto detailing professionals, with many options available to help keep your operation running efficiently.

In this article, we’ll go through the details of why a vehicle shop may need an air compressor, different types of air compressors available on the market, and how to select the perfect air conditioner for your professional detailing service.

Why Would a Vehicle Shop Use an Air Compressor?

Providing constant air pressure to a range of different activities in the shop, an air compressor is a vital tool in many automotive businesses, and for detailers, they can be used to blow dust out of hard to reach areas in car upholstery, cup holders, door jams, and similar tight spaces in a vehicle. It can also be used for exterior detailing, such as cleaning around door panels, operating pneumatic tools, or providing power for headlight restoration. Overall, having an air compressor to assist in the detailing process makes it much easier to give the customer a pristinely clean car at the end of the process.

A few examples of how an air compressor helps keep your business moving:

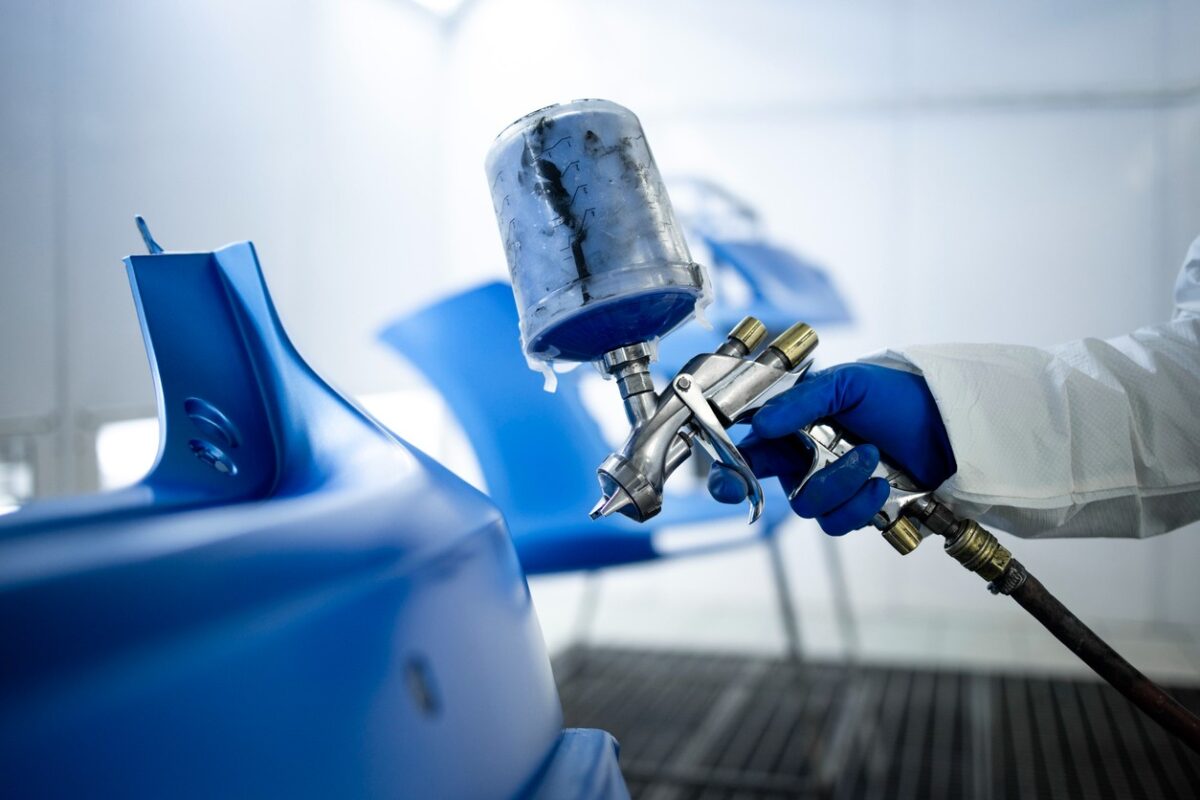

- Car painting: An air compressor provides an unbelievably smooth finish, especially to clear coat paints that can be somewhat fussy.

- Tire inflation: You want to leave customers feeling they got an amazing value and checking tires on the way out is one way to do that.

- Cleaning your engine bay: Dirt and grime are endemic in auto shops and being able to blow dust out the overhead door makes cleanup simple.

- Drying off a car: Bumpers, side mirrors, hood vents, grills and similar areas are notoriously stubborn to get dry. Blow the excess moisture out.

- High Pressure cleaning: Nothing gets dirt out of tight places like using high pressure, and the right air compressor helps make that happen.

- Powers a car cleaning gun: Whether you’ve got a Tornador Z-010 or similar cleaning tools, you’ll need an air compressor to power it.

Types of Air Compressors for Car Detailing Available at AAV:

There are two different types of air compressor you can use for car detailing, a rotary screw compressor and a piston compressor. Let’s take a look at each type:

Rotary Screw Compressors

What are rotary screw compressors?

Rotary screw compressors provide constant air pressure by keeping the mechanism in motion constantly, with no downtime in the duty cycle. This type of compressor is very reliable and can provide a high airflow in terms of cubic feet per minute (CFM), but also tends to be a bit more expensive.

How do they work?

A rotary screw compressor is operated by trapping air between two rotors or interlocking helical screws. The volume of air that is trapped between these two screws will gradually be compressed, providing a constant source of compressed air.

Because of the simplicity of design, rotary screw compressors tend to be very reliable and provide a constant stream of pressurized air, which can be a boon if you’re dealing with air tools that use a great deal of air flow, such as a painting rig.

Use cases:

- Powering air tools

- Inflating tires

- Running spray guns

Piston Compressors

What is a piston compressor?

By comparison, a piston or reciprocating compressor uses an electric motor to compress air that has been taken into a cylinder, which is then moved into a large capacity bottle or tank. From this tank, the pressurized air is then moved through hoses to tools and similar equipment. Though both terms are correct, most in the industry use the term piston compressor.

Piston compressors are found in two primary configurations:

Single Stage Compressors

Designed for intermittent use, a single stage compressor uses one cylinder to compress the air. For this reason, it’s only able to reach lower pressures. They tend to work very well for smaller shops, individual workstations, or personal use. Due to their smaller size, capability, and simplicity, they tend to also be the least expensive type of air compressor on the market. They work well for inflating tires, cleaning shops, operating lower-power air tools, and similar applications.

Two Stage Compressors

By comparison, a two stage compressor is designed for near-continuous use. The two stages in this type of compressor refer to two cylinders, one larger and one smaller. The larger cylinder fills with air which is compressed by a piston and moved into the second, smaller cylinder. The second cylinder is then also compressed by a piston, after which point the air is moved into the storage tank. This process allows the air to be compressed to a higher pressure, making it more suitable for ongoing use as well as in higher-powered applications such as painting, sanding, and similar applications. However, due to the larger number of moving parts, they are typically more expensive to purchase up front, but have a lower overall maintenance cost due to less frequent maintenance being required.

Choosing an Air Compressor for Car Detailing: Things to Consider

There are many factors to take into consideration when selecting the right air compressor for your detailing needs.

Size

Size can refer to two different factors. The first, the weight of the air compressor, has to do with how stable it will be in operation. If you run a mobile service, you may want to go with a lighter horizontal-orientation air compressor, which will be more stable but still movable by the average worker. If you have a centralized shop, you may want to choose a heavier vertical-oriented air compressor that will remain stable while taking up less floor space.

The second factor has to do with tank size. The size of the air compressor tank will determine how much air it can move into the system during its duty cycle. If you’re considering a two cycle piston air compressor, you may get by with a smaller tank at a higher pressure than you could with a single stage air compressor. Air compressor tanks are typically measured in gallons.

CFM

Though air compressor tanks are measured in gallons, the amount of air they can move is measured in cubic feet per minute. This has to do with how much air can be compressed constantly by the air compressor if it’s running wide open.

PSI

PSI stands for pounds per square inch, which is a pressure measurement. A two stage compressor can handle higher PSI than a single stage, providing higher pressure to get the job done.

Portability

As mentioned under size, a heavier air compressor is better for a large shop, while mobile services will want to use a smaller air compressor that will often be easier to move.

Best Air Compressors for Car Detailing

CR7.5 Gas Powered Air Compressor: The Most Reliable Piston Air Compressor

Featuring a two-stage compressor, 30-gallon tank size, 7.5 horsepower motor, and a flow rate of approximately 23.5 CFM at 100 PSI and 22.6 CFM at 175 PSI, the CR7.5 is the most reliable piston-based air compressor we stock at Advanced Air. It works very well for many larger shops, but may be too heavy if you need a portable unit.

Quincy Portable Air Compressor

If your operation is in need of a smaller, more portable option, this single stage air compressor from Quincy is a great option to consider. It can generate a maximum of 7.4 CFM at 135 PSI, features a 20-gallon powder-coated ASME tank, runs on 115V AC with a 2 horsepower motor, and is a great option to consider for most portable operations.

As you can see, there are many factors to consider when selecting your air compressor, whether you’re using it as a simple leaf blower for your shop, need something to move cleaning liquid deeper into the carpet, have to have something with enough power to handle the perfect ceramic coating, or just want a simple, oil-free pump that requires virtually no maintenance. At Advanced Air, we’re happy to help you find the perfect option. Please contact us today to get started!