Hello 5-Star Review Service and Installation!

Need a Service or Repair?

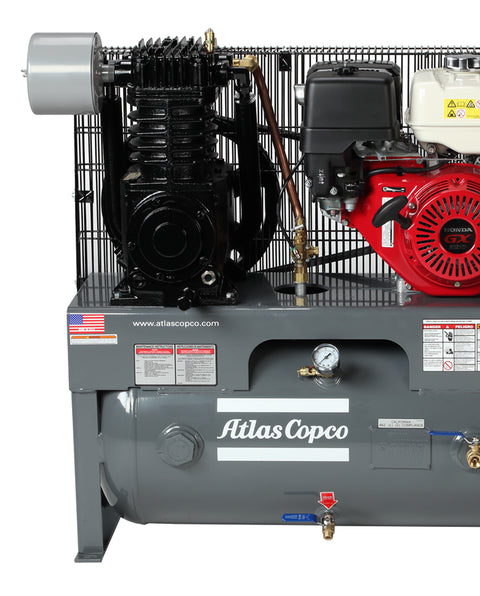

Our certified technicians are fully equipped to perform any of your maintenance or repair needs – ensuring your compressed air system operates efficiently and reliably.

Need an Install?

Air compressors, vacuum pump, dryer, piping and any other equipment your compressed air system needs to run optimally, we can install it all – even structural needs like a canopy, enclosure or any needed electrical.

Start a Maintenance Plan

Save time, money, and take the hassle out of maintenance and repairs by starting an automated service plan – while we ensure your equipment is serviced before issues arise.

Advanced saved us tons of money! The best compressor company we've used in our 15 years of business.

One of the best decisions I made when looking to hire a full service air & vac co to support my mfg company.

We use this company for the City of San Diego's industrial air, vacuum, and pump needs. Excellent service.

10 out of 10 recommend Advanced! They are extremely professional, knowledgeable and trustworthy.

Without any hesitation I would recommend Advanced to anyone seeking reliable and efficient service.

From start to finish I could not have imagined a better experience. Highly recommend Advanced to you.

Our system has been working great ever since the Advanced techs started servicing it. Very friendly too!

I have to say one of the best companies l've dealt with for preventative maintenance on my machines.

Defense, military, hospitals, healthcare, local mfg, breweries and more…

All get their equipment from Advanced.

You can too!

Our equipment sales team will expertly navigate you through a quality compressed air system, reach out today or visit one of our Showrooms.

Talk with Our Sales Team

We are here to help you get what you need, whether that's system design with turnkey installation for a new warehouse or manufacturing line or just new equipment for your existing operation, we're just a click or call away.

Showrooms

Setup to make your job easier, we stock Atlas Copco compressors and replacement parts, Prevost pipe and fittings, along with air dryers, filters, and treatment items ready for pickup or delivery.